Thank you for Subscribing to Electrical Business Review Weekly Brief

Electrical Business Review: Specials Magazine

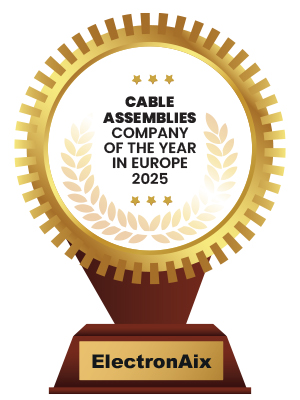

Meeting specifications on paper is easy. True quality is revealed when those specifications perform flawlessly in the real world. That’s the difference ElectronAix makes when it comes to manufacturing and distributing cable assemblies, flat flex cables and connectors for the industrial, sensor, automotive and medical sectors, where demands are as diverse as they are complex. “Cables are the silent enablers of seamless communication and operational stability under challenging conditions. We make sure the connections run smoothly to keep entire systems running reliably,” says Peter Stremmer, Managing Director. ElectronAix achieves this by transforming every high-stakes challenge into an opportunity for innovation. Combining deep industry knowledge with custom engineering, it delivers cable solutions that do more than just meet specifications. Take a client who was struggling with cable failures in a tight 5.5mm pipe. Standard assemblies, designed with a straight wire exit, required wires to be bent at a 90° angle after production—creating excessive mechanical stress and frequent cable failures. Instead of forcing a one-size-fits-all solution, ElectronAix designed a customised assembly with a built-in 90° cable exit and a maximum diameter of 5.2mm, ideally suited to the application. The new design simplified the customer’s assembly process, reduced operational risks and improved durability. Successes like this showcase ElectronAix’s expertise in automation and miniaturisation. Advanced techniques like automated crimping and soldering enable the crimping of connectors with pitches as small as 0.8 mm and wire gauges as fine as AWG 32, to deliver precision and reliability in every application. At the same time, its mastery of miniaturisation allows for micro-coaxial cable assemblies that support high data rates and frequencies. By achieving pitches as small as 0.25 mm and wire gauges as fine as AWG 50, ElectronAix’s soldering processes tackles even the most intricate design challenges. Its technical strength ensures that clients overcome their current obstacles and are equipped to meet future technological demands with confidence. A Supply Chain that Never Misses a Beat Custom design and manufacturing are just one part of the equation at ElectronAix. Supply chain and inventory management are equally critical in ensuring that every solution reaches clients on time. Planning plays a pivotal role in this game. From the earliest design phase, existing assemblies are available for initial tests, assessments and prototyping, allowing clients to refine their designs with real-world components. Even before production begins, ElectronAix secures critical parts—such as connectors and raw cables—so they are ready for processing while final adjustments are made. Long-standing partnerships in Taiwan, Vietnam and Thailand help in enhancing the supply chain agility, where efficiency with uncompromising quality is perfectly balanced. Through a cooperation partner in Taipei, Taiwan, ElectronAix finds the optimal balance between automated processing and the required quality standards (ISO, UL, IATF, VDA, AS9100), tailoring solutions to meet each client’s needs. This global synergy allows ElectronAix to deliver custom, high-quality cable solutions with responsiveness and reliability, which prevents supply chain disruptions and keeps projects moving forward.

Electrical Infrastructure Safety Company of the Year in Europe

Shermco has established itself as North America’s premier electrical testing and maintenance services provider, setting industry standards in safety, reliability, and innovation. Since its founding in 1974, the company has grown exponentially, now operating over 40 service centers across the United States and Canada. As a NETA-accredited organization, Shermco delivers an extensive range of services, including electrical testing, maintenance, engineering, and workforce training. What sets Shermco apart in the electrical solutions space is its unwavering commitment to safety, integrity, teamwork, and customer-driven innovation. At the core of Shermco’s operations is a deep-rooted commitment to safety. The company prioritizes the well being of its employees and clients, ensuring that every project is executed with strict adherence to safety protocols. By fostering a culture where safety comes first, Shermco not only protects its workforce but also enhances the reliability and longevity of the electrical systems it services. This emphasis on safety is not just a guideline but a fundamental aspect of Shermco’s identity. Integrity is another key pillar of Shermco’s success. The company operates under the principle of always doing what is right, ensuring transparency and ethical decision-making in all aspects of business. This commitment to integrity fosters trust among clients and employees, reinforcing long term relationships and delivering consistent, high-quality service. By cultivating an environment where accountability and honesty are paramount, Shermco continues to uphold its reputation as a trusted leader in electrical testing solutions. Collaboration is at the heart of Shermco’s approach to problem-solving. The company thrives on teamwork, bringing together skilled professionals to develop innovative solutions that drive efficiency and safety. Employees are encouraged to challenge existing processes, seek out improvements, and work collectively to overcome challenges. This culture of innovation ensures that Shermco remains at the forefront of the electrical services industry, providing clients with cutting-edge solutions tailored to their specific needs. A key differentiator for Shermco is its extensive service offerings. The company provides a comprehensive suite of electrical solutions, ranging from transformer maintenance and protection services to rotating machinery repairs and wind energy field services. Its engineering capabilities cover compliance engineering, field engineering services, and advanced power system analysis, ensuring that clients receive end-to-end support for their electrical infrastructure. Additionally, Shermco’s in-shop services, including ISO certified motor and generator repair, offer clients top-tier expertise and reliability. Disaster recovery services further showcase Shermco’s ability to restore electrical systems quickly and safely, minimizing downtime and financial loss for businesses.

High-Performance Electronic Test Equipment Company of the Year in Europe

Siglent Technologies Co., Ltd. has emerged as a global leader in the design and manufacture of electronic test and measurement instruments. Established in 2002, the company has continually pushed the boundaries of innovation to provide high-quality, feature-rich products at competitive prices. Siglent’s unwavering commitment to research and development has allowed it to establish a strong foothold in the industry, making advanced technology accessible to engineers and technicians worldwide. The journey of Siglent began with the development of digital oscilloscopes, marking its entry into the test and measurement domain. Over the years, the company’s product portfolio has expanded to include isolated handheld oscilloscopes, function/ arbitrary waveform generators, DC power supplies, digital multimeters, spectrum analyzers, and other general test instruments. This wide array of products has positioned Siglent as a one-stop solution for professionals seeking reliable and cost-effective testing equipment. A key factor behind Siglent’s success is its emphasis on research and development. The company consistently allocates more than 15% of its total sales revenue to R&D, fostering continuous technological advancements. This dedication has resulted in numerous patents and industry-leading innovations. For instance, in 2005, Siglent’s EasyHunting technology significantly enhanced the precision of oscilloscopes, outperforming similar models in the market. Such breakthroughs highlight Siglent’s unique selling proposition— delivering professional-grade performance without the premium price tag. Siglent has also expanded its global footprint strategically, reinforcing its presence in key markets. In 2014, the company established its North American headquarters in Ohio, USA, enhancing its ability to provide localized inventory, sales, technical support, and services. This move ensured faster response times to customer needs, strengthening relationships with partners and end users. Additionally, Siglent operates a branch office in Augsburg, Germany, further solidifying its reach in the European market. These expansions underline the company’s commitment to offering world class service and support to its growing international customer base. One of the most significant milestones in Siglent’s corporate journey was its successful listing on the sci-tech innovation board of the Shanghai Stock Exchange in December 2021. This achievement not only marked Siglent as the first company in the general electronic test and measurement instrument industry to list on the A-share market in China but also underscored its financial strength and credibility in the industry.

CXO INSIGHTS

The Vision for the Future of Appliances, Electrical, and Electronics Manufacturing

Greg Hoffman, Director, Cable Products Segment, Molex

Future of Digitalised Aerospace Industry

Bruno Cervia, VP R&D, Pilatus Aircraft Ltd

Revamping the Future of CNC Machining Space

Alex Rose-Parfitt, Engineering Director, Raytheon UK

In the Tension between Price Increases and Supply Chain Problems- With 3D Printing for Acute Problem Solving

Ralf Anderhofstadt, Head of Center of Competence Additive Manufacturing - Daimler Trucks & Buses, Daimler Buses | EvoBus GmbH

Green Hydrogen Fabrication Prepared for Gigawatt Scale

Dr. Sebastian Neubert, Operations Officer H2 Projects New Energy Business, Siemens Energy AG

IN FOCUS

Overcoming Challenges in the Wire and Cable Industry with Smart Solutions

Sustainability and regulatory compliance should be at the forefront to meet evolving market demands and contribute to a greener future.

Driving Innovation: Key Factors Shaping Europe's Cable Assembly Market

The cable assembly industry is a crucial segment within Europe's broader electrical and electronics sector.

EDITORIAL

Enhancing Connectivity and Efficiency in Modern Industries

Cable assemblies, often referred to as harnesses, are bundles of cables and wires encased in a protective sheath to facilitate signal transmission and power distribution. These assemblies serve as the backbone of numerous electronic and mechanical systems, ensuring proper functionality and operational efficiency. Whether in a medical device, a military-grade communication system, or a high-speed data center, cable assemblies are designed to meet specific performance requirements while withstanding harsh environmental conditions.

With the rise of IoT, 5G, and AI-driven applications, cable assemblies must support higher data rates, improved bandwidth, and enhanced connectivity. Manufacturers are incorporating advanced shielding and fiber optic technologies to meet these evolving demands. As industries focus on reducing their environmental footprint, the use of recyclable materials and lead-free manufacturing processes is gaining traction. Eco-friendly cable assemblies contribute to sustainability while maintaining high performance.

The integration of robotics and AI-driven systems in cable assembly production enhances precision, reduces human error, and speeds up manufacturing processes. Automated testing and quality assurance further ensure that the final products meet rigorous industry standards. The demand for compact and lightweight electronic devices has led to the development of miniaturized cable assemblies. These solutions enable manufacturers to design smaller, more efficient products without compromising connectivity or durability.

The evolution of cable assembly solutions is essential in supporting the rapid advancements of modern industries. As technology continues to advance, the need for reliable, high-performance, and customized cable assemblies will only grow. By embracing innovation, sustainability, and automation, manufacturers can ensure that these critical components meet the demands of an increasingly connected world. Investing in high-quality cable assemblies not only enhances operational efficiency but also ensures the longevity and reliability of essential systems across diverse industries.