I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info

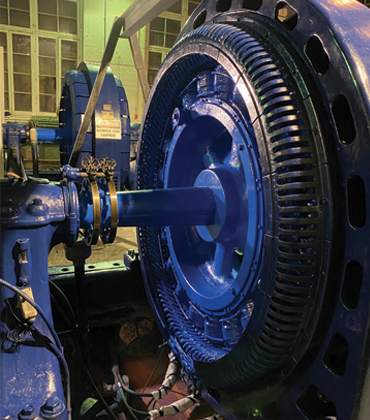

In the world of motor and generator repair, reliability isn’t just about fixing what’s broken—it’s about preventing future failures and ensuring long-term performance. That’s the philosophy that drives Renown Electric Motors & Repairs Inc. The company doesn’t just repair motors; it works to uncover the root causes of failures, reduce downtime, and provide lasting solutions that keep businesses running efficiently.

“At Renown, service isn’t just something we provide—it’s part of who we are,” says Jeff Collins, Partner. “We don’t just want to fix a problem today; we want to help our customers minimize future breakdowns. That’s why we take a comprehensive approach to repairs, maintenance, and reliability.”

Renown Electric serves industries where uptime is critical, including hydroelectric, manufacturing, mining, elevators, infrastructure, oil and gas, water treatment, and wind power. A significant portion of its work involves hydroelectric generators, with projects spanning from major power companies to independent operators. It also works on a mix of primary and backup power systems, covering everything from industrial-scale LNG operations to smaller, specialized generators.

With in-house coil manufacturing, advanced diagnostics, and expertise in both AC and DC motors, Renown Electric is more than just a repair shop—it’s a reliability partner for industries that can’t afford downtime.

Mastering In-House Manufacturing

Renown Electric handles almost everything in-house, manufacturing the majority of its own coils. The company has both small and large motor coil shops and a generator facility can operate around the clock, enabling it to rewind a motor even at midnight or complete a task within 24 hours. This eliminates the need to rely on external suppliers for coil or part manufacturing.

For example, Renown Electric recently worked with a client on a project to rebuild coils for a hydroelectric generator from the 1920s with a specialized coil design. The coils required for this 40-megawatt generator were no longer available on the market, and no supplier was even willing to quote a price for the replacement.

Renown Electric’s in-house manufacturing capabilities and expertise in replicating obsolete designs made the company irreplaceable in this scenario. Instead of restacking and redoing the laminations, the team crafted an exact-match coil, saving the client millions of dollars.

The solution was further enhanced by seamless integration with the company’s machining capabilities, expertly managed by coil design engineers and specialists in insulation systems and motor technology.

Renown Electric’s expertise in DC motors also provides a competitive edge, handling more than 150 DC motors per month, ranging from 1 horsepower to 8,000 horsepower. This level of specialization is rare and reflects the depth and breadth of the company’s capabilities.

The shops are also equipped with comprehensive testing facilities. While the small motor shop can test up to 4,160 volts, the large motor and generator shop can handle up to 13.8k volts. The test stands capture and report all relevant data and offer witness testing for clients who want to be involved in the process. Although many larger motor shops offer similar facilities, Renown Electric’s ability to deliver these services locally makes it a distinct player in the industry.

A Team of Expertise, Innovation, and Legacy

The company’s outstanding performance is driven by a team of experts who bring commitment and technical excellence to every project. With a workforce of approximately 75 individuals, the team includes seasoned professionals who have been winding motors since they were 14 and are now in their 60s, alongside young skilled workers recruited from college with complementary skills. Renown Electric also brings in skilled workers globally through an employment visa program, with the goal of retaining them for the long term.

The team excels in electric and mechanical motor repair, overhaul, remanufacturing, field service, and engineering support, handling projects up to 50,000 to 60,000 horsepower. Production supervisors track progress throughout the shop, while project managers ensure each task remains transparent from start to finish. Whether it’s scoping an initial project, designing a custom coil, or refining timelines and plans, the team’s collaborative approach makes every challenge achievable.

The team excels in electric and mechanical motor repair, overhaul, remanufacturing, field service, and engineering support, handling projects up to 50,000 to 60,000 horsepower. Production supervisors track progress throughout the shop, while project managers ensure each task remains transparent from start to finish. Whether it’s scoping an initial project, designing a custom coil, or refining timelines and plans, the team’s collaborative approach makes every challenge achievable.

With its diverse skill set, Renown Electric has built a longstanding reputation in the industry, accumulating a wealth of intellectual capital. The company has also developed an in-house training and mentorship program, allowing younger talent to enter the motor and generator repair trade.

As seasoned team members approach retirement, Renown Electric pairs them with younger workers, ensuring that critical industry knowledge is passed down. For example, veteran employees bring expertise in handling complex projects, such as working with an armature from a 100-ton generator, where experience is invaluable.

While experienced members showcase the company’s capabilities, the quality control team ensures everything is executed flawlessly. Adhering to ISO 9001:2015 and EASA standards, Renown Electric consistently meets industry regulations and ensures its workforce remains well-trained and up-to-date on certifications.

By maintaining a strong focus on quality management, the company is not just enhancing current offerings—it is also investing in new technologies to improve motor operations. Whether integrating artificial intelligence with vibration analysis, current signature analysis, or other advanced diagnostic methods, Renown Electric is always exploring ways to enhance reliability and extend the time between failures.

“We want clients to understand that we never entertain recurring issues. We don’t just sit back and let problems repeat themselves without taking action,” says Collins.

This commitment to continuous improvement is at the heart of the company’s approach to business and client relationships. No matter how big or complex the task, Renown Electric delivers unmatched service with precision and care. As a trusted motor and generator repair shop, the company doesn’t just meet expectations— it consistently surpasses them, fostering long-term relationships through exceptional value and high performance.

The solution was further enhanced by seamless integration with the company’s machining capabilities, expertly managed by coil design engineers and specialists in insulation systems and motor technology.

Renown Electric’s expertise in DC motors also provides a competitive edge, handling more than 150 DC motors per month, ranging from 1 horsepower to 8,000 horsepower. This level of specialization is rare and reflects the depth and breadth of the company’s capabilities.

The shops are also equipped with comprehensive testing facilities. While the small motor shop can test up to 4,160 volts, the large motor and generator shop can handle up to 13.8k volts. The test stands capture and report all relevant data and offer witness testing for clients who want to be involved in the process. Although many larger motor shops offer similar facilities, Renown Electric’s ability to deliver these services locally makes it a distinct player in the industry.

A Team of Expertise, Innovation, and Legacy

The company’s outstanding performance is driven by a team of experts who bring commitment and technical excellence to every project. With a workforce of approximately 75 individuals, the team includes seasoned professionals who have been winding motors since they were 14 and are now in their 60s, alongside young skilled workers recruited from college with complementary skills. Renown Electric also brings in skilled workers globally through an employment visa program, with the goal of retaining them for the long term.

The team excels in electric and mechanical motor repair, overhaul, remanufacturing, field service, and engineering support, handling projects up to 50,000 to 60,000 horsepower. Production supervisors track progress throughout the shop, while project managers ensure each task remains transparent from start to finish. Whether it’s scoping an initial project, designing a custom coil, or refining timelines and plans, the team’s collaborative approach makes every challenge achievable.

With its diverse skill set, Renown Electric has built a longstanding reputation in the industry, accumulating a wealth of intellectual capital. The company has also developed an in-house training and mentorship program, allowing younger talent to enter the motor and generator repair trade.

As seasoned team members approach retirement, Renown Electric pairs them with younger workers, ensuring that critical industry knowledge is passed down. For example, veteran employees bring expertise in handling complex projects, such as working with an armature from a 100-ton generator, where experience is invaluable.

While experienced members showcase the company’s capabilities, the quality control team ensures everything is executed flawlessly. Adhering to ISO 9001:2015 and EASA standards, Renown Electric consistently meets industry regulations and ensures its workforce remains well-trained and up-to-date on certifications.

By maintaining a strong focus on quality management, the company is not just enhancing current offerings—it is also investing in new technologies to improve motor operations. Whether integrating artificial intelligence with vibration analysis, current signature analysis, or other advanced diagnostic methods, Renown Electric is always exploring ways to enhance reliability and extend the time between failures.

“We want clients to understand that we never entertain recurring issues. We don’t just sit back and let problems repeat themselves without taking action,” says Collins.

This commitment to continuous improvement is at the heart of the company’s approach to business and client relationships. No matter how big or complex the task, Renown Electric delivers unmatched service with precision and care. As a trusted motor and generator repair shop, the company doesn’t just meet expectations— it consistently surpasses them, fostering long-term relationships through exceptional value and high performance.

“At Renown, service isn’t just something we provide—it’s part of who we are,” says Jeff Collins, Partner. “We don’t just want to fix a problem today; we want to help our customers minimize future breakdowns. That’s why we take a comprehensive approach to repairs, maintenance, and reliability.”

Renown Electric serves industries where uptime is critical, including hydroelectric, manufacturing, mining, elevators, infrastructure, oil and gas, water treatment, and wind power. A significant portion of its work involves hydroelectric generators, with projects spanning from major power companies to independent operators. It also works on a mix of primary and backup power systems, covering everything from industrial-scale LNG operations to smaller, specialized generators.

With in-house coil manufacturing, advanced diagnostics, and expertise in both AC and DC motors, Renown Electric is more than just a repair shop—it’s a reliability partner for industries that can’t afford downtime.

Mastering In-House Manufacturing

Renown Electric handles almost everything in-house, manufacturing the majority of its own coils. The company has both small and large motor coil shops and a generator facility can operate around the clock, enabling it to rewind a motor even at midnight or complete a task within 24 hours. This eliminates the need to rely on external suppliers for coil or part manufacturing.

-

We don’t just want to fix a problem today; we want to help our customers minimize future breakdowns. That’s why we take a comprehensive approach to repairs, maintenance, and reliability

For example, Renown Electric recently worked with a client on a project to rebuild coils for a hydroelectric generator from the 1920s with a specialized coil design. The coils required for this 40-megawatt generator were no longer available on the market, and no supplier was even willing to quote a price for the replacement.

Renown Electric’s in-house manufacturing capabilities and expertise in replicating obsolete designs made the company irreplaceable in this scenario. Instead of restacking and redoing the laminations, the team crafted an exact-match coil, saving the client millions of dollars.

The solution was further enhanced by seamless integration with the company’s machining capabilities, expertly managed by coil design engineers and specialists in insulation systems and motor technology.

Renown Electric’s expertise in DC motors also provides a competitive edge, handling more than 150 DC motors per month, ranging from 1 horsepower to 8,000 horsepower. This level of specialization is rare and reflects the depth and breadth of the company’s capabilities.

The shops are also equipped with comprehensive testing facilities. While the small motor shop can test up to 4,160 volts, the large motor and generator shop can handle up to 13.8k volts. The test stands capture and report all relevant data and offer witness testing for clients who want to be involved in the process. Although many larger motor shops offer similar facilities, Renown Electric’s ability to deliver these services locally makes it a distinct player in the industry.

A Team of Expertise, Innovation, and Legacy

The company’s outstanding performance is driven by a team of experts who bring commitment and technical excellence to every project. With a workforce of approximately 75 individuals, the team includes seasoned professionals who have been winding motors since they were 14 and are now in their 60s, alongside young skilled workers recruited from college with complementary skills. Renown Electric also brings in skilled workers globally through an employment visa program, with the goal of retaining them for the long term.

The team excels in electric and mechanical motor repair, overhaul, remanufacturing, field service, and engineering support, handling projects up to 50,000 to 60,000 horsepower. Production supervisors track progress throughout the shop, while project managers ensure each task remains transparent from start to finish. Whether it’s scoping an initial project, designing a custom coil, or refining timelines and plans, the team’s collaborative approach makes every challenge achievable.

The team excels in electric and mechanical motor repair, overhaul, remanufacturing, field service, and engineering support, handling projects up to 50,000 to 60,000 horsepower. Production supervisors track progress throughout the shop, while project managers ensure each task remains transparent from start to finish. Whether it’s scoping an initial project, designing a custom coil, or refining timelines and plans, the team’s collaborative approach makes every challenge achievable.With its diverse skill set, Renown Electric has built a longstanding reputation in the industry, accumulating a wealth of intellectual capital. The company has also developed an in-house training and mentorship program, allowing younger talent to enter the motor and generator repair trade.

As seasoned team members approach retirement, Renown Electric pairs them with younger workers, ensuring that critical industry knowledge is passed down. For example, veteran employees bring expertise in handling complex projects, such as working with an armature from a 100-ton generator, where experience is invaluable.

While experienced members showcase the company’s capabilities, the quality control team ensures everything is executed flawlessly. Adhering to ISO 9001:2015 and EASA standards, Renown Electric consistently meets industry regulations and ensures its workforce remains well-trained and up-to-date on certifications.

By maintaining a strong focus on quality management, the company is not just enhancing current offerings—it is also investing in new technologies to improve motor operations. Whether integrating artificial intelligence with vibration analysis, current signature analysis, or other advanced diagnostic methods, Renown Electric is always exploring ways to enhance reliability and extend the time between failures.

“We want clients to understand that we never entertain recurring issues. We don’t just sit back and let problems repeat themselves without taking action,” says Collins.

This commitment to continuous improvement is at the heart of the company’s approach to business and client relationships. No matter how big or complex the task, Renown Electric delivers unmatched service with precision and care. As a trusted motor and generator repair shop, the company doesn’t just meet expectations— it consistently surpasses them, fostering long-term relationships through exceptional value and high performance.

The solution was further enhanced by seamless integration with the company’s machining capabilities, expertly managed by coil design engineers and specialists in insulation systems and motor technology.

Renown Electric’s expertise in DC motors also provides a competitive edge, handling more than 150 DC motors per month, ranging from 1 horsepower to 8,000 horsepower. This level of specialization is rare and reflects the depth and breadth of the company’s capabilities.

The shops are also equipped with comprehensive testing facilities. While the small motor shop can test up to 4,160 volts, the large motor and generator shop can handle up to 13.8k volts. The test stands capture and report all relevant data and offer witness testing for clients who want to be involved in the process. Although many larger motor shops offer similar facilities, Renown Electric’s ability to deliver these services locally makes it a distinct player in the industry.

A Team of Expertise, Innovation, and Legacy

The company’s outstanding performance is driven by a team of experts who bring commitment and technical excellence to every project. With a workforce of approximately 75 individuals, the team includes seasoned professionals who have been winding motors since they were 14 and are now in their 60s, alongside young skilled workers recruited from college with complementary skills. Renown Electric also brings in skilled workers globally through an employment visa program, with the goal of retaining them for the long term.

The team excels in electric and mechanical motor repair, overhaul, remanufacturing, field service, and engineering support, handling projects up to 50,000 to 60,000 horsepower. Production supervisors track progress throughout the shop, while project managers ensure each task remains transparent from start to finish. Whether it’s scoping an initial project, designing a custom coil, or refining timelines and plans, the team’s collaborative approach makes every challenge achievable.

With its diverse skill set, Renown Electric has built a longstanding reputation in the industry, accumulating a wealth of intellectual capital. The company has also developed an in-house training and mentorship program, allowing younger talent to enter the motor and generator repair trade.

As seasoned team members approach retirement, Renown Electric pairs them with younger workers, ensuring that critical industry knowledge is passed down. For example, veteran employees bring expertise in handling complex projects, such as working with an armature from a 100-ton generator, where experience is invaluable.

While experienced members showcase the company’s capabilities, the quality control team ensures everything is executed flawlessly. Adhering to ISO 9001:2015 and EASA standards, Renown Electric consistently meets industry regulations and ensures its workforce remains well-trained and up-to-date on certifications.

By maintaining a strong focus on quality management, the company is not just enhancing current offerings—it is also investing in new technologies to improve motor operations. Whether integrating artificial intelligence with vibration analysis, current signature analysis, or other advanced diagnostic methods, Renown Electric is always exploring ways to enhance reliability and extend the time between failures.

“We want clients to understand that we never entertain recurring issues. We don’t just sit back and let problems repeat themselves without taking action,” says Collins.

This commitment to continuous improvement is at the heart of the company’s approach to business and client relationships. No matter how big or complex the task, Renown Electric delivers unmatched service with precision and care. As a trusted motor and generator repair shop, the company doesn’t just meet expectations— it consistently surpasses them, fostering long-term relationships through exceptional value and high performance.

Thank you for Subscribing to Electrical Business Review Weekly Brief