Thank you for Subscribing to Electrical Business Review Weekly Brief

Electrical Business Review: Specials Magazine

How can power systems deliver higher density, greater efficiency and seamless scalability to meet today’s most demanding applications? Vicor answers these critical questions with its comprehensive modular power components and complete power systems portfolio. From the initial concept to the final deployment, it efficiently optimizes every step of the power system design process for modern data centers. At the core of its innovation are power modules transforming how we think about power delivery, offering an alternative to traditional solutions. These modules pack unprecedented power density into incredibly compact and lightweight designs—up to five times denser than conventional systems and weighing as little as 674mg—an essential factor for industries where space and weight are at a premium. While conventional setups scatter heat unpredictably, Vicor ensures uniform and predictable heat dissipation. This means simplified thermal management that enhances the overall reliability of the systems, making integration smoother and more predictable. Vicor’s exceptional plug-and-play solutions eliminate the need for expensive system overhauls and minimize downtime, making it a go-to choice for manufacturers where every second and every watt matters. Designed to support industries like industrial automation, high-performance computing, robotics, transportation, and manufacturing, it delivers easy-to-deploy solutions for power delivery networks that provide the highest density and efficiency from source to the point of load. “We have always believed that highly automated U.S. manufacturing with vertical integration, close collaboration between product development, manufacturing processes, and operations is key to synergistic value opportunities leveraging best-in-class products,” says Patrizio Vinciarelli, president and chief executive officer.

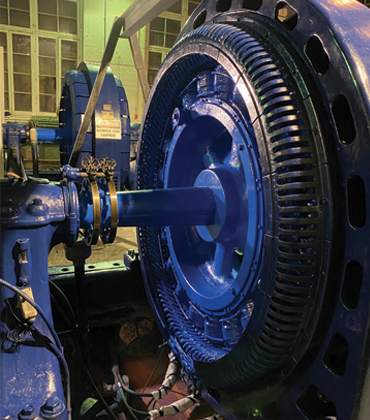

Electric Generator Repair Service of the Year in Canada 2025

In the world of motor and generator repair, reliability isn’t just about fixing what’s broken—it’s about preventing future failures and ensuring long-term performance. That’s the philosophy that drives Renown Electric Motors & Repairs Inc. The company doesn’t just repair motors; it works to uncover the root causes of failures, reduce downtime, and provide lasting solutions that keep businesses running efficiently. “At Renown, service isn’t just something we provide—it’s part of who we are,” says Jeff Collins, Partner. “We don’t just want to fix a problem today; we want to help our customers minimize future breakdowns. That’s why we take a comprehensive approach to repairs, maintenance, and reliability.” Renown Electric serves industries where uptime is critical, including hydroelectric, manufacturing, mining, elevators, infrastructure, oil and gas, water treatment, and wind power. A significant portion of its work involves hydroelectric generators, with projects spanning from major power companies to independent operators. It also works on a mix of primary and backup power systems, covering everything from industrial-scale LNG operations to smaller, specialized generators. With in-house coil manufacturing, advanced diagnostics, and expertise in both AC and DC motors, Renown Electric is more than just a repair shop—it’s a reliability partner for industries that can’t afford downtime. Mastering In-House Manufacturing Renown Electric handles almost everything in-house, manufacturing the majority of its own coils. The company has both small and large motor coil shops and a generator facility can operate around the clock, enabling it to rewind a motor even at midnight or complete a task within 24 hours. This eliminates the need to rely on external suppliers for coil or part manufacturing. For example, Renown Electric recently worked with a client on a project to rebuild coils for a hydroelectric generator from the 1920s with a specialized coil design. The coils required for this 40-megawatt generator were no longer available on the market, and no supplier was even willing to quote a price for the replacement.

CXO INSIGHTS

Motivating and Challenging Technical Professionals in a Manufacturing Environment

Scott Marcus, Process Engineering Manager, Flex-N-Gate

Maintaining Efficient Workflow Processes

Isaiah Lever, Manager of Composite Manufacturing, Airbus Helicopters

Sustainable Packaging - A Sustainable Business Approach

Titilope Omidiran, PhD., Global ESG Manager, Hunter Amenities International Ltd.

Building Confidence with Competence

Chris Stamp, Corporate Health, Safety and Environment Manager, MasTec Canada

Navigating the Evolving Landscape of Construction Management

Emily Pencer, Project Manager, Roxboro Excavation Inc

Unravelling the Opportunities in Construction Industry

Tony Cook, Project Director, PCL Construction

Navigating the Future of Retail Construction

Seamus Farnan, Vice President, Construction - Store Development, Earls Kitchen + Bar

IN FOCUS

Navigating the Testing Landscape for Battery Management Systems in Canada

Engineers can overcome the obstacles by adopting advanced testing methodologies, leveraging simulation tools, and staying aligned with evolving industry standards.

EDITORIAL

Elevating Generator Repair with Technology

Reports highlight that the Canada generator sets market, valued at $776.2 million in 2025, is expected to reach $1,159.2 million by 2030, at a CAGR of 8.4 percent.

Fueling this growth are several emerging technologies that are reshaping the generator repair service industry. Predictive maintenance powered by IoT sensors enables real-time monitoring and early fault detection, helping reduce downtime and repair costs. Remote monitoring systems further enhance service efficiency by allowing technicians to track generator performance in real-time and respond quickly to issues before they escalate. Digital twin technology also plays an instrumental role by creating virtual models of generators, allowing for accurate diagnostics and more effective maintenance planning.

This edition of Electrical Business Review Canada delves into how emerging technologies are reshaping the generator repair service industry. It features insights from Isaiah Lever, manager of composite manufacturing at Airbus Helicopters Canada, who emphasizes the significance of fostering a cohesive work environment to drive efficiency, retain expertise and align team efforts with company-wide goals in aerospace manufacturing. Scott Marcus, process engineering manager, Flex-N-Gate, highlights that open communication, respect and appreciation are fundamental to effectively motivating and retaining both experienced and less experienced technical professionals.

We hope this edition offers valuable perspectives on how businesses can stay resilient and competitive in a rapidly changing energy landscape through innovation and strategic adaptation.